In the field of manufacturing printed scarves, the variety of available techniques opens up a wide range of possibilities for personalisation and the quality of the end product. If you want to print a scarf, there are various high-quality methods to choose from. One of the most outstanding options is digital printing, or traditional screen printing and specialised weaving techniques.

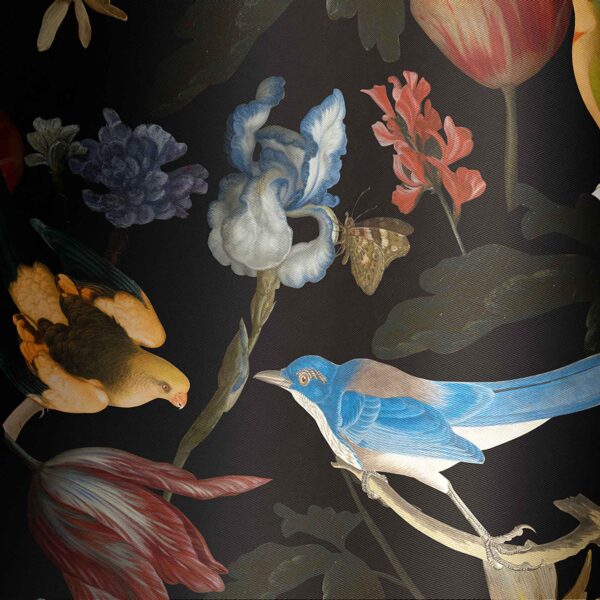

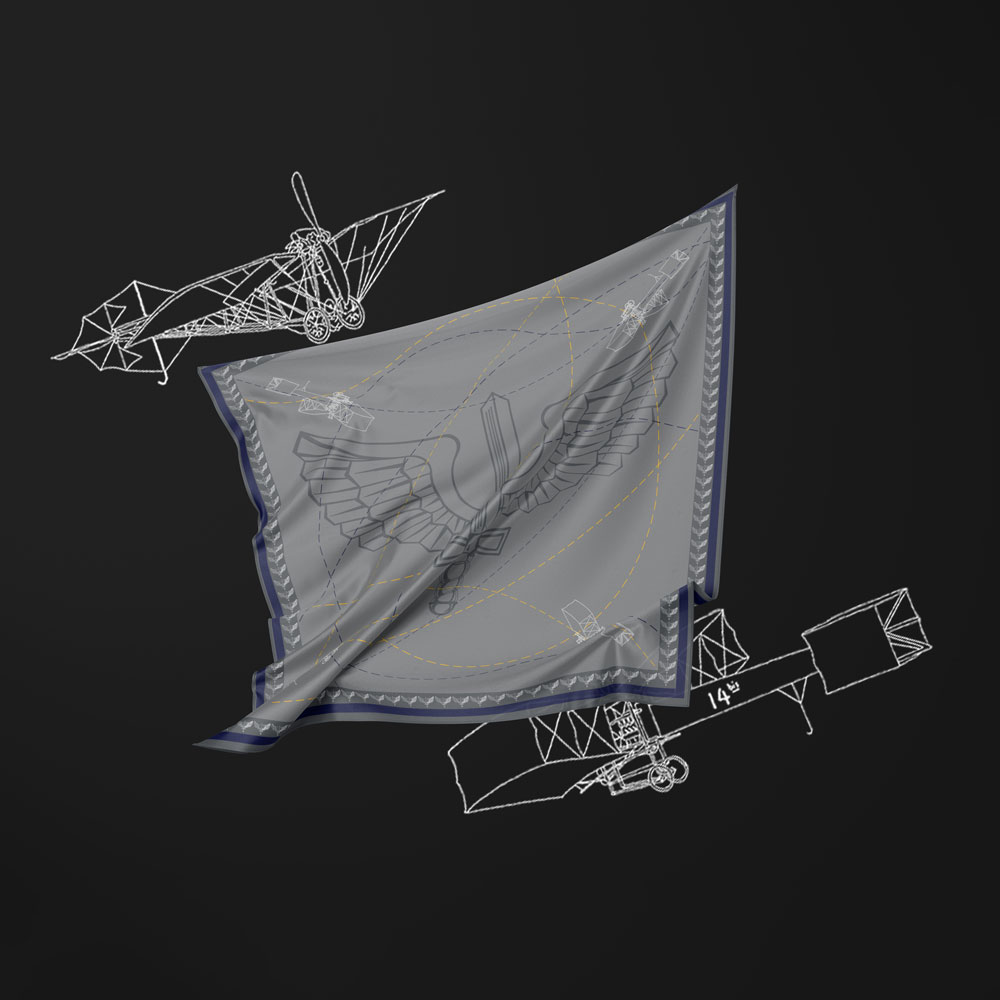

The use of digital printing has revolutionised the textile industry by turning every printed scarf into an individual piece of art. The fidelity to the original design is simply impressive and makes each piece unique.

On the other hand, traditional screen printing offers a sense of authenticity. Through this technique, the designs are applied to the scarves with carefully crafted stencils, giving each piece a craftsmanship quality and a distinctive touch.

Finally, specialized weaving opens up a world of possibilities in terms of textures and surfaces. From soft and lightweight fabrics to more structured and durable options.

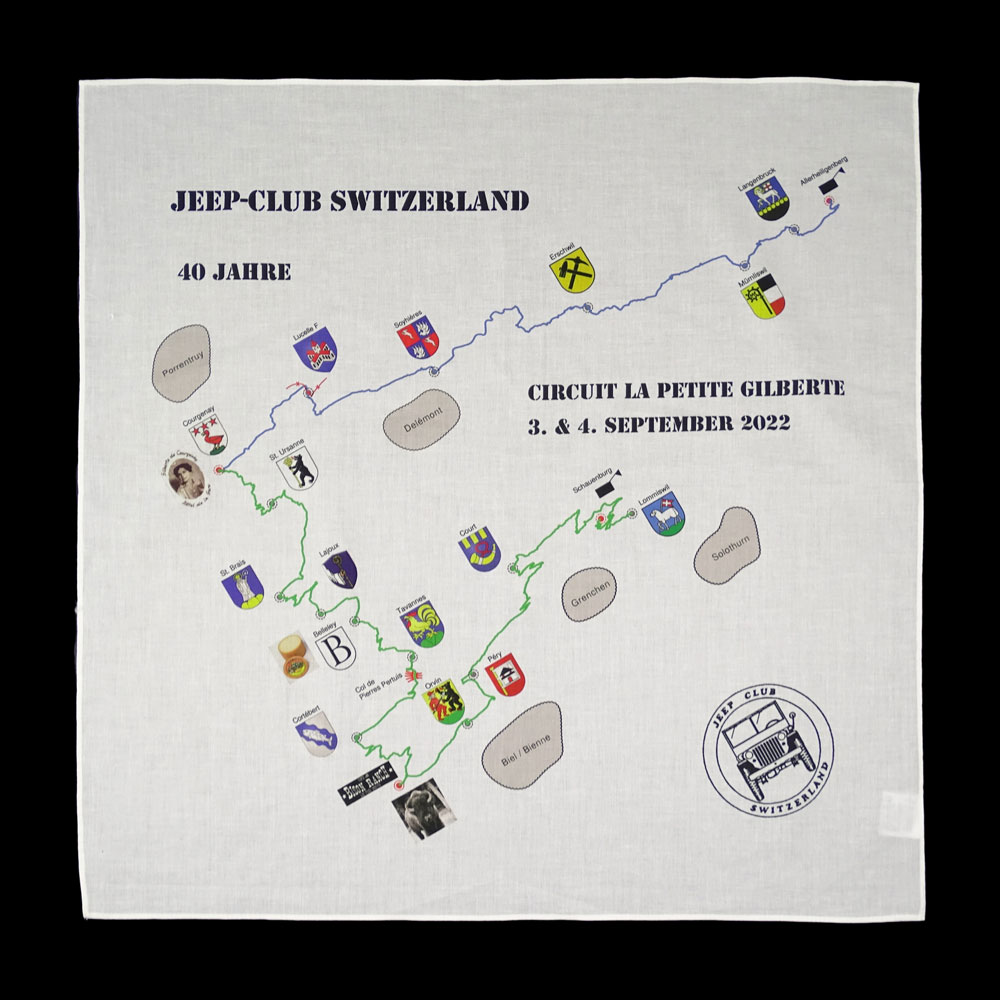

Printing scarves with stencils

Printing a traditional scarf with stencils is an art deeply rooted in the history of the textile industry, giving each piece a unique charm and craftsmanship. This process involves creating special stencils that are carefully designed to transfer patterns and designs onto the surface of the scarves.

The process begins with the production of the stencils, which can be made from a variety of materials such as wood, metal, or even linoleum. These stencils are intricately carved, taking into account every detail of the desired design.

Once the templates are ready, the ink or paint is carefully applied to them to ensure an even distribution. Subsequently, the templates are pressed onto the fabric of the scarf, transferring the design with exceptional precision and clarity.

The end result is a printed scarf that reflects the beauty of craftsmanship and attention to detail. Each piece is unique, with a distinctive character that stands out in its execution. The traditional printing of scarves with stencils not only offers exceptional quality, but also a touch of nostalgia and authenticity that is appreciated in contemporary fashion.

Requirements and benefits of printing scarves with stencils

Requirements

- Clarity and simplicity

The design should be clear and simple so that it can be easily transferred onto the scarf. Too complicated details or degradations are not suitable for printing with stencils, as they could be lost in the process.

- Contrast

Well-defined contrasts between colors and shapes facilitate the transfer of the design onto the scarf and ensure a clear and precise appearance in the final product.

- The right size

The design should adapt to the size of the scarf and the area to be printed on. It is important to consider the dimensions and proportions of the scarf to ensure that the design looks good and is centered.

- Appropriate scale

The design should be scalable without losing quality and sharpness, therefore it must always be a vectorized file (ai, eps, pdf, svg).

Advantages

- Durability and opacity

The ink used in stencil printing penetrates deep into the fabric, ensuring that the design is visible and sharp on both sides of the scarf, providing a uniform and professional appearance.

- Cost

Compared to digital printing, stencil printing with shapes tends to be more cost-effective, especially for large production quantities. This makes it an attractive option for companies looking for a cost-effective solution for personalizing scarves.

- Efficiency in production

Once the templates are prepared, the printing process can be carried out quickly and efficiently, leading to agile production and a rapid response to market demand, especially compared to more elaborate methods such as screen printing.

The minimum quantity for custom production of printed scarves with templates

For the production of printed scarves with patterns, there is a slightly higher minimum order quantity than usual, which is offset by using a more cost-effective technique.

- 100% Silk

- 100% Microfiber

- 100% Polyester

- 100% Cotton

- and other materials

- Blends

Get scarf printed using digital printing process

Having a scarf printed using digital printing technology has completely transformed the personalization process in the textile industry. This revolutionary technique enables the creation of detailed and vibrant designs with exceptional fidelity to the original.

Instead of using conventional methods such as screen printing or embossing, digital printing on printed scarves utilizes state-of-the-art technology to apply the designs directly onto the fabric. This process is fast and precise, resulting in an exact reproduction of the desired patterns and colors.

The versatility of digital printing allows for complete personalization of printed scarves, starting from the selection of designs to the combination of colors and the inclusion of complex details. Furthermore, this technique does not require mold making, making it a more accessible option for small productions.

Digital printing on printed scarves offers exceptional quality and optimal durability. Whether for brand promotion, adding a personal touch to an event, or simply expressing creativity, printing scarves with this technique is a modern, efficient, and high-quality option.

Requirements and benefits of printed scarves with digital printing

Requirements

- Clear Details

The design should have clear and defined details so that they can be printed correctly on the scarf. It is advisable to avoid using too small or delicate elements that could be lost during printing.

- Design size

The design must fit the actual size of the scarf. It is important to consider the proportions of the scarf to ensure that the design looks good and is centered.

- Appropriate resolution

The design should have a high resolution to ensure sharpness and print quality. A resolution of at least 300 dpi (Dots per Inch) is recommended to avoid the image looking pixelated or blurry. The recommended file types are TIFF, JPG, and PNG in CMYK color mode.

Advantages

- Flexibility of designs

With digital printing, there are no limitations regarding the complexity of designs. Detailed images, smooth color gradients, and small texts can be printed with exceptional clarity, offering great creative freedom.

- Fast production

Digital printing is a fast and efficient process that allows for shorter production times compared to traditional methods such as die-cutting. This is particularly beneficial for rush orders or small-scale productions.

- Quality and durability

Digital printing offers exceptional print quality and optimal durability. The colours remain vivid even after multiple washes, ensuring that the scarves look fresh and attractive in the long term.

Minimum quantity for custom production of printed scarves with digital printing

For the production of printed scarves using digital printing, there is a minimum production quantity that is ideal for small runs.

- 100% Silk

- 100% Microfiber

- 100% Polyester

- 100% Cotton

- and other materials

- Blends

Print Jacquard scarves

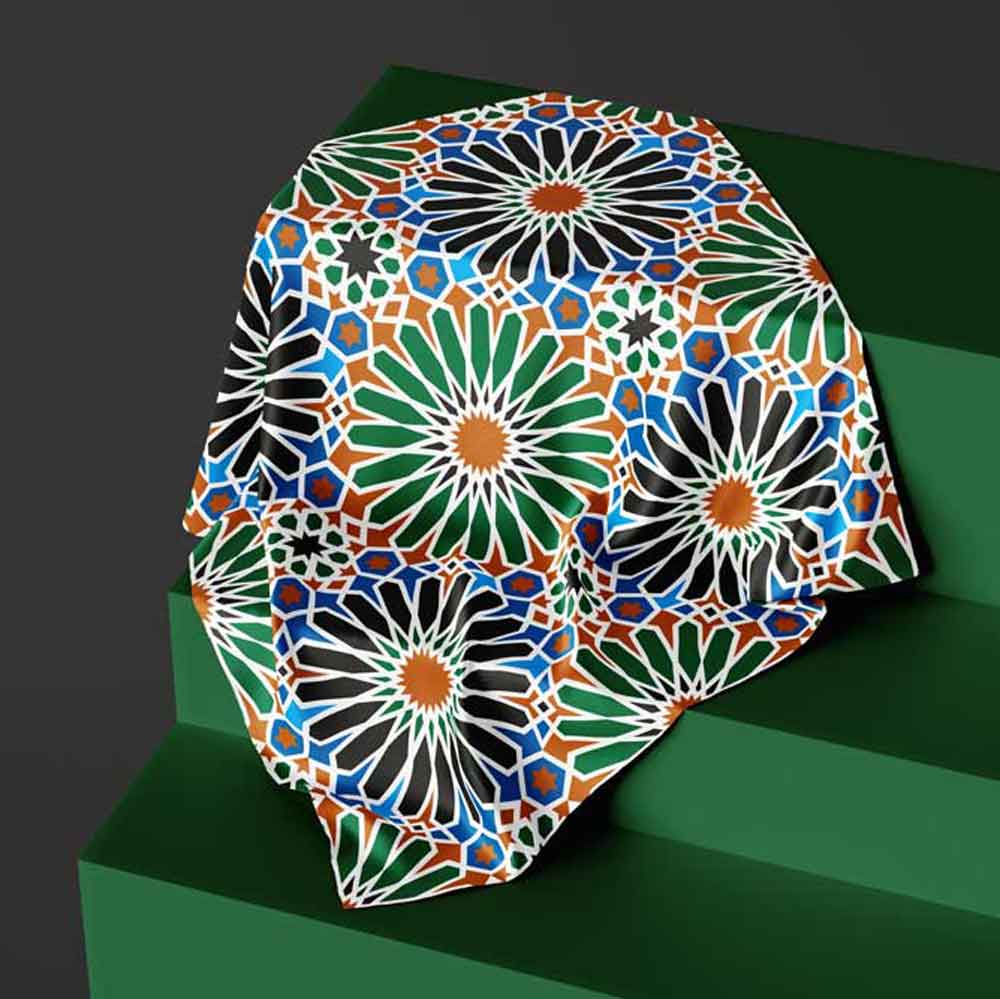

Jacquard fabric is a specialized weaving technique that allows for the creation of complex and detailed patterns in fabrics, including scarves. This technique is named after the inventor of the Jacquard loom, Joseph Marie Jacquard, who developed a mechanism in the 19th century that enabled the automated production of complex patterns.

The production of scarves from Jacquard fabric involves the use of a specialized loom that either uses a series of punch cards or an electronic system with perforated cards to control the lifting of individual threads. These punch cards or the electronic system determine the pattern that is woven into the fabric.

Jacquard fabric allows for a variety of designs, from simple to extremely elaborate, with the ability to incorporate floral motifs, geometric patterns, landscapes, and even portraits. This is achieved by manipulating the threads on the loom to create raised and recessed fabric areas, resulting in the formation of the desired patterns.

One of the characteristic features of Jacquard fabric is its reversibility, meaning that the pattern is visible on both sides of the fabric, making it ideal for scarves where the aesthetic appearance on both sides is important.

The requirements and benefits of Jacquard woven scarves

Requirements

- Design clarity

The design should be clear and distinct so that it can be accurately translated into Jacquard fabric. Too small details can be lost in the weaving process, so it is important that the design is clear and large enough to be reproduced accurately.

- Symmetry

The symmetry of the design must be perfect, especially important for recurring patterns or symmetrical designs.

- Design size

The size of the design should be appropriate for the size of the scarf and for the size of the Jacquard loom. It is important to consider the physical dimensions of the scarf and the loom when creating the design.

Advantages

- Reversibility

An outstanding feature of Jacquard fabric is its reversibility. This means that the design is visible on both sides of the fabric, allowing for an aesthetically pleasing appearance and greater versatility in the use of the scarf.

- Visual quality

Jacquard woven scarves tend to be durable and resistant to wear and tear. This is due to the quality of the fabric and the weaving process that uses high-quality yarns to create a strong and resilient fabric.

- Durability

Woven Jacquard scarves tend to be durable and resistant to wear and tear. This is due to the quality of the fabric and the weaving process that uses high-quality yarns to create a strong and durable fabric.

The minimum quantity for custom-made printed scarves

For the production of woven scarves, there is a higher minimum order quantity than usual, as it is an extremely specific technique that requires a more elaborate weaving preparation. However, the extraordinary quality of this technique compensates with an extremely exquisite and luxurious result.

- All materials

Printed scarves - stencil printing vs. digital printing vs. jacquard weaving

Comparison table of different techniques for making scarves

| Traditional production with templates | Digital printing | Jacquard fabric | |

|---|---|---|---|

| Minimum production quantity | From 100 pieces | From 50 pieces | From 300 pieces |

| The design on the back of the scarf | |||

| Allows colour gradients | |||

| Production costs | Inexpensive | Moderate | High |

| Required file type | ai, eps, pdf | tiff, png, jpg | ai, eps, pdf |

Print last completed projects for scarves

External links: